We offer various IBR boilers and hot air generators for various operation in Chemical Textile and Dyes industries.

Multi fuel fired, three pass fully wet back and semi wet back design.

High thermal inertia to maintain pressure & temperature.

Large water holding capacity.

Large steam water separation height.

Excellent performance compared to FBC & membrane boiler.

Rocking type fire grates arrangement to reduce “Cold air losses” & easy ash removal.

Amazing “fuel saving” in twin furnace design.

Fully factory assembled & no special foundation required.

Virtually 100 % dry saturated steam (practically no carry over).

Fully independent flue circuits.

Better turndown ratio and operational efficiency.

Good accessibility means ease of maintenance.

1. Single furnaced solid fuel fired boiler

Fuel: coal, wood , lignite, agro waste briquettes, baggase, rice husk,, groundnut shell or any other solid fuel.

Manufacturing under internationally accepted inspection agencies i.e. IBR, lloyd’s, SGS, bureau, veritas,TUV or any other as per client’s requirements.

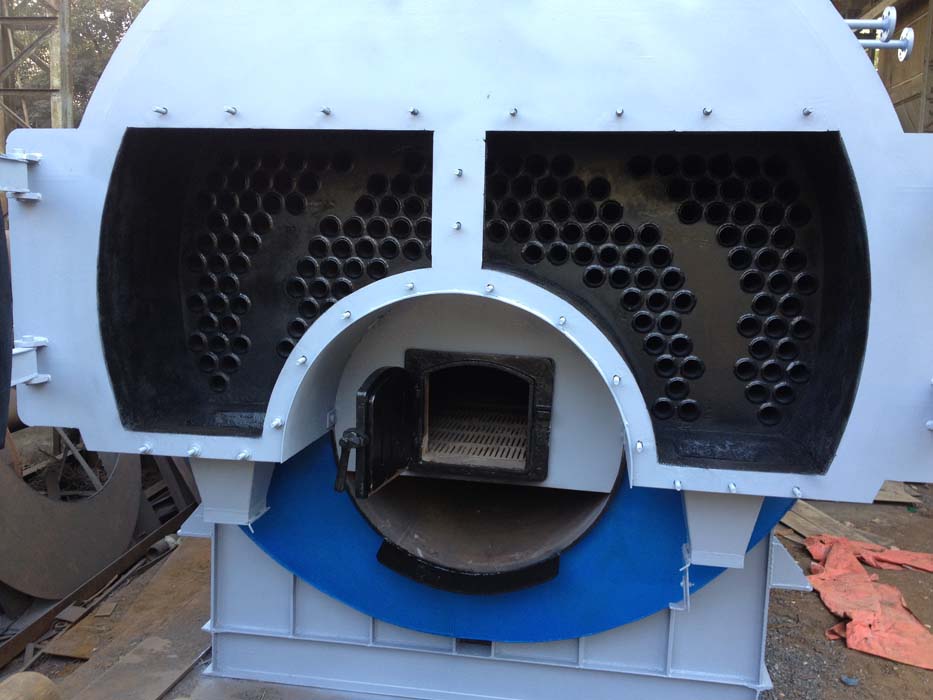

2. Double furnaced solid fuel fired boiler

Fuel: coal, wood , lignite, agro waste briquettes, baggase, rice husk,, groundnut shell or any other solid fuel.

Manufacturing under internationally accepted inspection agencies i.e. IBR, lloyd’s, SGS, bureau, veritas,TUV or any other as per client’s requirements.

Unique Feature

In double furnace Design there are two furnaces for firing and two individual fule paths till outlet of the boiler, so you can oprate only one furnace during part load condition and saving energy.

Improvisation/Option of oprating Boiler on one furnace and simultaneously to clean the other furnace including tubes.

Two furnace with two reversing chamber design have amazing fule saving compared to duble furnace have a single reversing chamber and single I.D. fan.

3. Water wall type external Furnace Boiler